By Don Sullivan

Photos by the author

Attending The WoodenBoat Show at Mystic Seaport Museum in Mystic, Connecticut in June of 2018, I spotted a beautiful yet hearty double-ended yawl tied up to one of the in-water exhibits. I walked by a few times, never spoke to anyone, but never forgot the boat either. The following year, I returned to the show and there she was again! I introduced myself to Geoff Kerr, the builder of this boat and approximately 15 other Caledonia Yawls. We sat in his cockpit for about a half hour as I shared my desire to build one myself; Geoff was most encouraging, even though he builds these boats for a living. As I drove home from Mystic that day a wave of emotion came over me…I am going to build that boat. Much like, I imagine, a calling a priest receives from God…there was no scenario left where I wasn’t going to build that boat. I immediately bought a set of plans from Iain Oughtred, the boat’s designer who resides in Isle of Skye, Scotland.

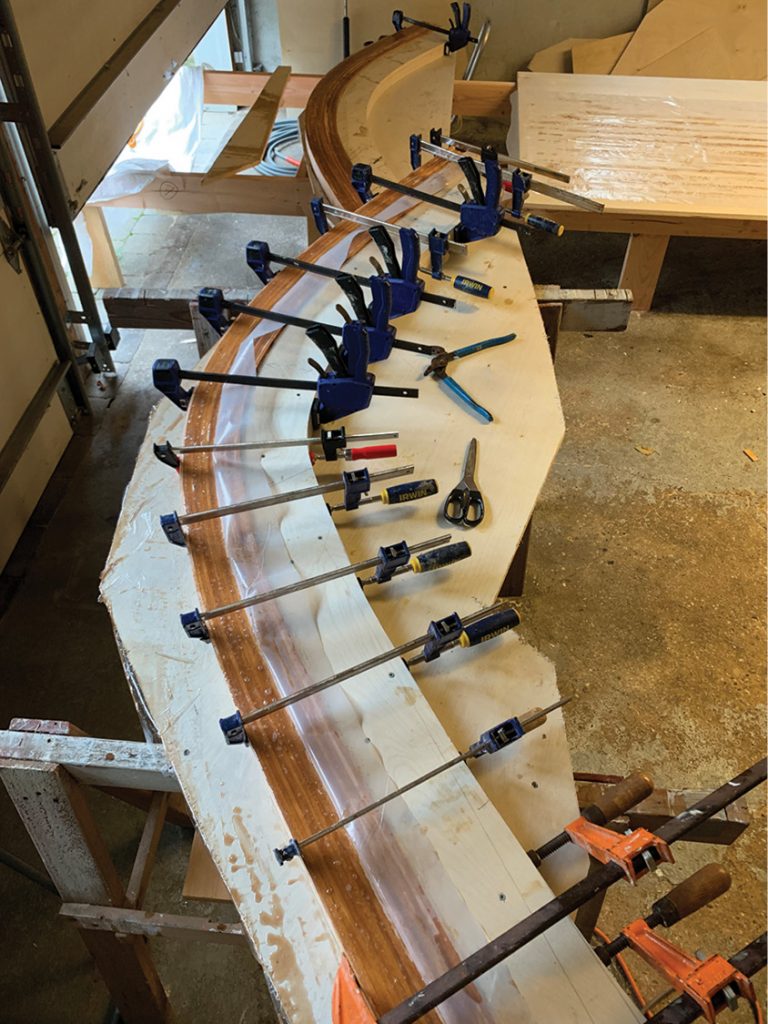

Laminating the forward and aft stems on their respective molds.

Unfolding a set of boat plans for the first time can be intimidating, especially for a novice boat builder, but Iain offers some very sound advice: “Every journey begins with a single step, and boatbuilding is, after all, a matter of cutting out pieces of wood and putting them together. Time spent studying the plans before beginning is time well spent; the mists of confusion will gradually clear.” I took his advice to heart and built the entire boat in my head many times before starting; instructive online videos from Geoff Kerr and others proved indispensable.

Attaching the keelson and forward inner stem to the building frame and molds

I started building in September of 2019, putting in approximately thirty hours per week. Working completely alone, I finished her in January 2020, about 500 hours in total.

Attaching the keelson and forward inner stem to the building frame and molds

A Caledonia Yawl is 19’6’’ LOA with a hefty 6’6’’ beam, configured with a lug rigged mainsail and mizzen (other sail configurations are optional). She is built with modern technology often referred to as glued-lap construction, an attractive and efficient boatbuilding method for both traditional and modern wooden boats. The boat gains both its strength and beauty from the lapstrake construction combined with modern adhesives like epoxy.

In retrospect, the project can be broken down into the following major steps: the building frame and molds, the keelson and stems (fore & aft), planking, rails and interior, spars, and painting.

Constructing open rails

Iain provides excellent full-size drawings for the station molds with the plans. However, I choose to purchase pre-cut molds from Hewes & Co in Blue Hill, Maine rather than build myself; a shortcut that I think was well worth it, albeit expensive.

Gluing the Birds Mouth mast

Early on you must build the stems, which give the Caledonia its gorgeous sweeping bow and stern lines, and form a large part of the hull’s backbone. The stems are built over two molds (bow & stern) from lines taken directly off the plans, by laminating upwards of twenty or more 3/16” x 2” x 8’ pieces of Douglas Fir, then clamping and gluing them as one piece onto the mold (see photo). When this rather challenging step is complete, you are officially a boat builder.

Adding 15 pounds of molten lead to the centerboard for ballast

Once the stems and keelson are laid over the molds, faired into each other and secured, the planking can begin. This is a time consuming repetitive step that takes patience, especially when working alone. There are fourteen planks on a Caledonia Yawl II (eight on a Caledonia Yawl I) and they are installed garboard plank first (closest to the keel) out to the sheer plank (forming the outer edge of the vessel). Lapstrake construction (planks overlapping) requires a lot of edge beveling to ensure a tight fit between planks and a flush fit with the stems at the bow and the stern. I was able to do one plank per day.

With planking complete, the boat can be turned over revealing her beautiful lines for the first time, and one then can begin work on the rails and interior. I prefer the “open rails” that you see in the photos, but there are options and personal preferences here as well. The thwarts, floorboards and the mast partners (a thwart with a mast passing through it for stabilization) can be fitted quite easily, but everything should be painted before actually attaching to the boat. Locating the mast partners and mast steps to establish the correct rake for each mast requires precise measurements directly from the plans…fingers crossed that mine are correct.

Outfitting the interior

The spars are next, a major project that can be done in conjunction with other work like prepping and painting the interior pieces. The main mast is the biggest challenge – the recommendation is that it be hollow in order not to carry too much weight aloft. I used the Birds Mouth construction method, cutting eight 1” x 1.5” x 20’ tapered pieces of Sitka Spruce out of a single 1” x 12” x 20’ piece, and then routing a 90-degree angle out of one side of each stick. When fitted into each other they form a beautiful circle.

The rest of the spars (mizzen mast, mizzen boom, main boom, main yard, and boomkin) can all be solid wood; again, I used Sitka Spruce because of its light weight and relatively high strength. These spars are tapered on a table saw in their square format according to precise widths from the plans, then they are planed and sanded down to round. A Spar Makers Gauge is a cool homemade device that is worth Googling. It helps you align the planing depths regardless of the tapered width of the spar at any given point, and will probably give you your first chance to use the Pythagorean Theorem since high school.

A completed Caledonia Yawl, ready for rigging

Painting the hull is the final step. I chose to put a two-part epoxy sealer on the planks, stems and interior pieces, followed by a primer, and two coats of topside low-luster finish from historic marine paint purveyor George Kirby. The rails are varnished with a new water-based varnish from Total Boat – a fabulous product. I plan to christen the boat Sparge and launch her in April of 2020. ■

Don Sullivan and his wife Dawn have lived in Westport, CT since 1979, and have been avid boat owners and sailors for 40 years. They’ve owned a 28-foot gaff-rigged sloop, a Drascombe Lugger, a Pearson Ensign, and a 1966 Hinckley Pilot 35. Don built a Lumberyard Skiff in 2018.